Polyarylates (Aromatic Polyesters)

Properties

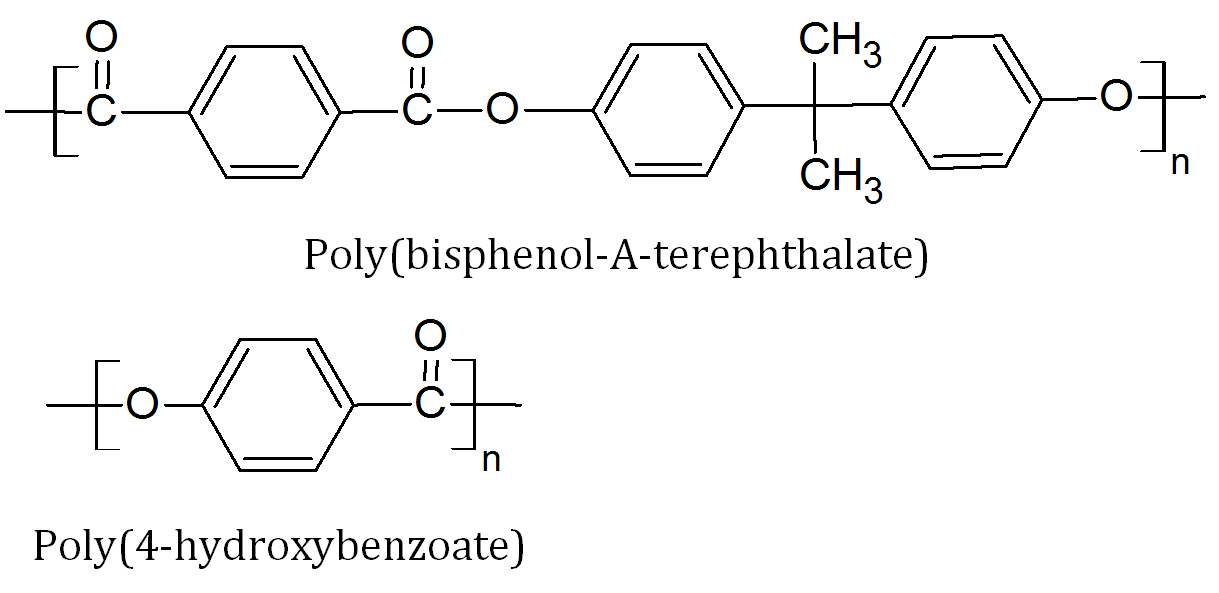

Polyarylates are a family of aromatic polyesters. The repeat units consists of ester groups (chemical formula -CO-O-) and aromatic rings. They are produced by polycondensation of a diacid chloride derivative of a dicarboxylic acid with a phenolic compound. The dicarboxylic acid is usually terephthalic or isophthalic acids and the phenol is Bisphenol A or a derivate of it. The bulky aromatic rings and the absence of methylene groups in the polymer backbone greatly stiffen the polymer chain by interfering with the rotation of the repeat units around the ester linkages. The two most common polyarylates are poly(-p-hydroxybenzoate) and polybisphenol-A terephthalate. The chemical structure of these arylates is given below.

Polybisphenol-A terephthalate is the most common polyarylate. It has one of the highest-levels of heat resistance among transparent resins. For example, its deflection temperature under 1.8 MPa load is about 175 °C (345 °F) (Ardel Polyarylate). It also has high transparency and excellent resistance to degradation from ultraviolet radiation. The material undergoes a molecular rearrangement resulting in the formation of a protective layer that essentially serves as a UV stabilizer. Because UV irradiation increases the UV-blocking property of the polymer, it exhibits excellent weather resistance without addition of any stabilizers. (Although some yellowing occurs, there is hardly any change in physical properties.) Arylates have a transparency as high as PC or PMMA, transmitting almost 90% light. The polymer exhibits excellent elastic recovery and has a high tolerable strain ratio. It also has excellent creep resistance and retains its properties for an extended period of time. For these reasons, the polymer can be used as springs.

Some other notworthy arylate monomers are 4-acetoxybenzoic acid, 4-hydroxybenzoic acid, hydroxynaphthalene-2-carboxylic acid, and 4-pivaloyloxybenzoic acid. The polymer Ekonol produced by Saint-Gobain, is based on 4-hydroxybenzoic acid. It is a highly crystalline linear thermoplastic polymer with no melting point and virtually no creep below 350 °C. It retains good stiffness at temperatures up to 315°C and, at temperatures around 425°C, it undergoes a second-order transition and becomes malleable and can be forged like ductile metals. Some other properties are high heat resistance, dielectric strength, elastic modulus, thermal conductivity, and good resistance to wear and solvents. It is also good machinable. Poly(hydroxybenzoate) can be blended with polytetrafluoroethylene (PTFE). This composite material is self-lubricating and has excellent temperature and wear resistance. Another important polyarylate is the Vectran fiber, manufactured by Kuraray. It is produced by polycondensation of 4-hydroxybenzoic acid and 6-hydroxynaphthalene-2-carboxylic acid and has similar good properties.

COMMERCIAL Arylates

Commercial grades of polyarylates are available under the trade names

Blends of poly(4-hydroxybenzoic acid) resin with polytetrafluoroethylene are sold under the Ekonol trademark. These grades are self-lubricating and and have good fatigue-resistance.

APPLICATIONS

Because of their excellent mechanical and electrical properties and excellent chemical stability, arylates are used in a variety of applications including automobiles, precision and medical devices, electronic displays and other electrical parts, semiconductor molding compounds, decorative displays and protective coverings. Due to their excellent resistance to degradation from ultraviolet radiation arylates also find uses in solar-energy panels. The Arylate-PTFE blends are used as self-lubricating bearings, O-ring seals, and pump vanes. Some other arylates are produced as fibers. Due to their high strength and durability, they are often used as reinforcing fibers for ropes, cables, and advanced composite materials.

Arylates are often a good choice for application where weathering effects are an issue.